Company introduction

The company has strong technical force and has a senior team

Experts and innovative technical backbone

The research and development team, and with the University of Jinan and other higher focus

The institutions have established a good mechanism for cooperative research. us

Adhering to the concept of "science and technology people-oriented", we focus on talents

Quality, high-tech development as a strategic goal, adhere to the "customer.

Households first, market-oriented "principle, to provide customers

Advantage products and services to create and share with partners

Successful value chain, the company has been based on research and development,

Has a strong R & D force, committed to technology innovation

New, the improvement of research and development strength and the completion of service system

Good.

The company is entering a new stage of development

Strong technical, manufacturing, purchasing, marketing and management excellence

Potential, with an excellent team to build Chinese car engines

Core component brand.

Business introduction

The company now produces mechanical and electronically controlled fuel systems to meet

Road diesel engine country III to country II, non-road country III and

Emission requirements for country IV. Widely used in automotive diesel engines, workers

Cheng machinery, generator set, ship machinery and other fields, the main products

Yes; Light, medium, heavy and heavy-duty common-rail fuel injection

Systems, SCR post-processing systems, mechanical in-line pumps and pumps

Nozzle, electric control in line pump system, imported foreign fuel system

Production technology, dedicated to the development of internal combustion engine intake system, low

Pressure hydrogen subsystem. Low pressure hydrogen subsystem: hydrogen ejector,

Hydrogen isolation valve, hydrogen safety valve, hydrogen circulation pump, has achieved the first batch

Customer samples, high pressure hydrogen subsystem completed A sample development

And some reliability tests; The hydrogen subsystem achieves electric increase

Pressure customer sample. To ensure high precision and reliability of products

The company will introduce advanced CNC and CNC from other developed countries

Testing equipment.

These products are supported by many domestic diesel engine factories.

And exported to America, the Middle East, Southeast Asia and other regions, annual sales

300 to 400 million.

Company product advantage

The injection nozzle produced by the company can match the three common rail series of Bosch, Denso and Delphi.

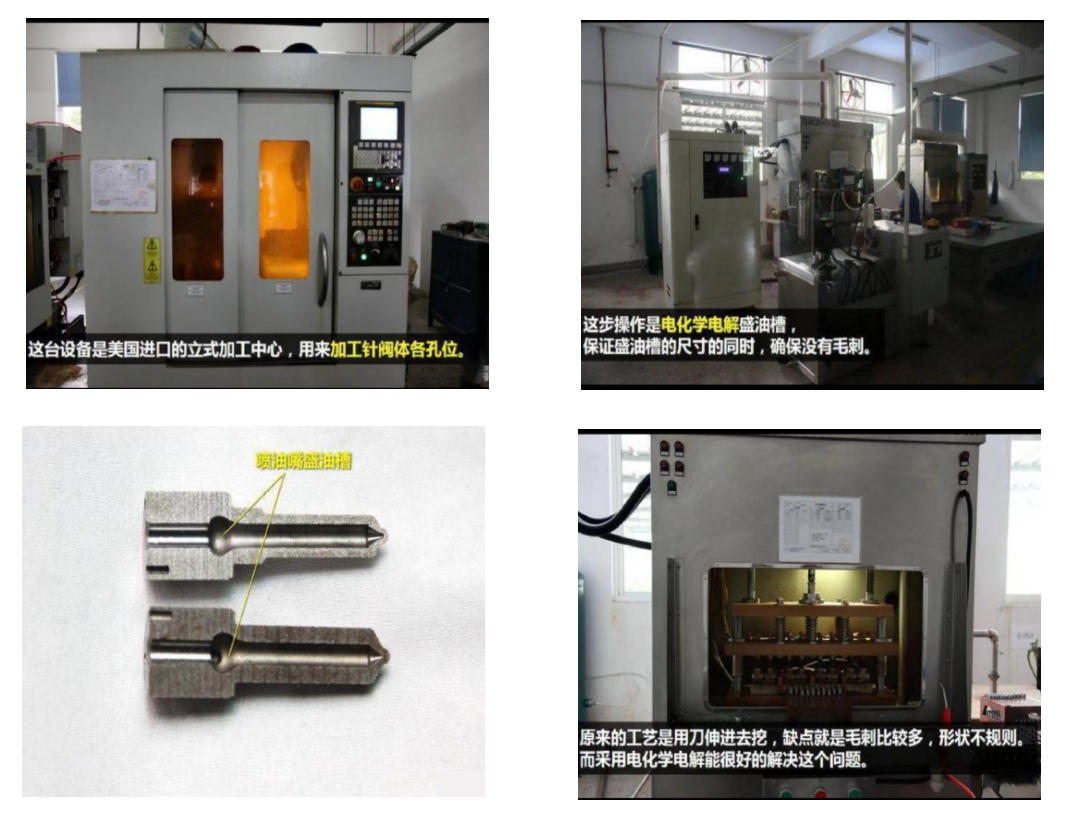

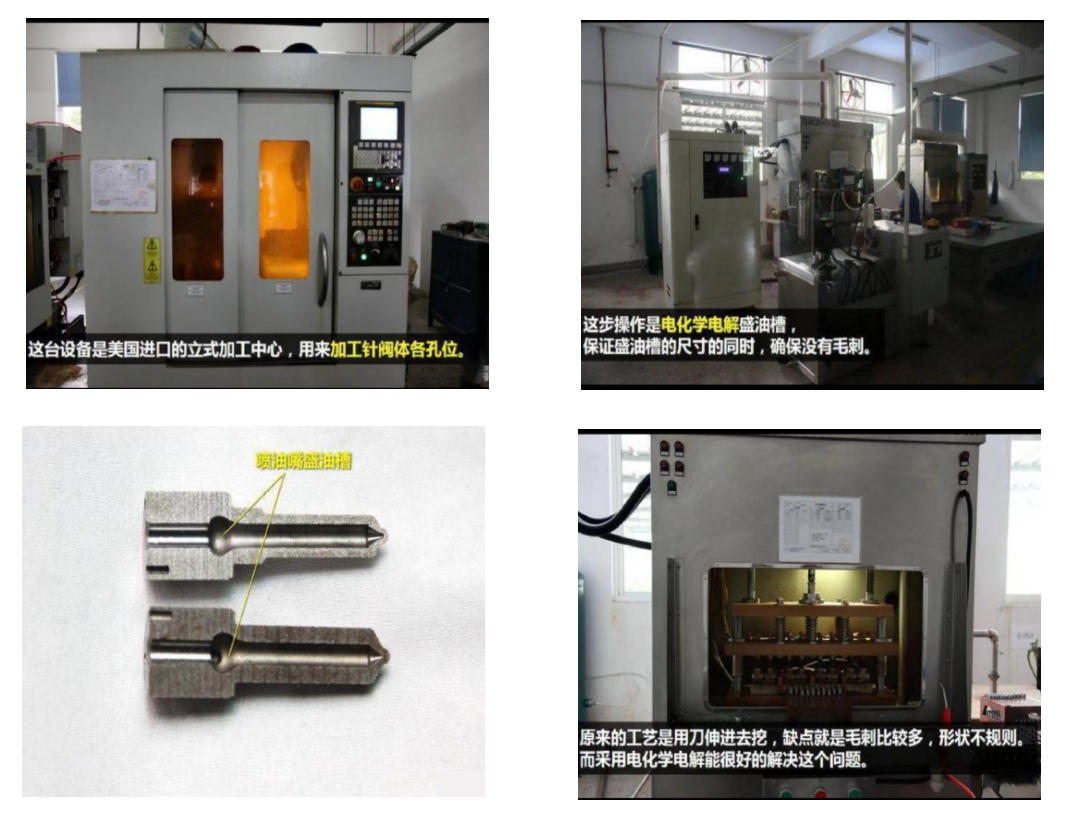

The oil nozzle is roughed by the imported Eurya quadricol drilling machine. Eurya quad drill once

Spray clamp, injector hole molding once, one processing molding can ensure concentricity, straightness and roughness

The degree meets the requirement. The use of electrochemical electrolysis tank to ensure the size of the tank while ensuring that there is no hair

S. The original process is to dig in with a knife, which is short for products with such high precision as the oil nozzle

The point is that there are more burrs and the shape is irregular, which can be solved well by electrochemical electrolysis

Question, this is also a big breakthrough for the company!

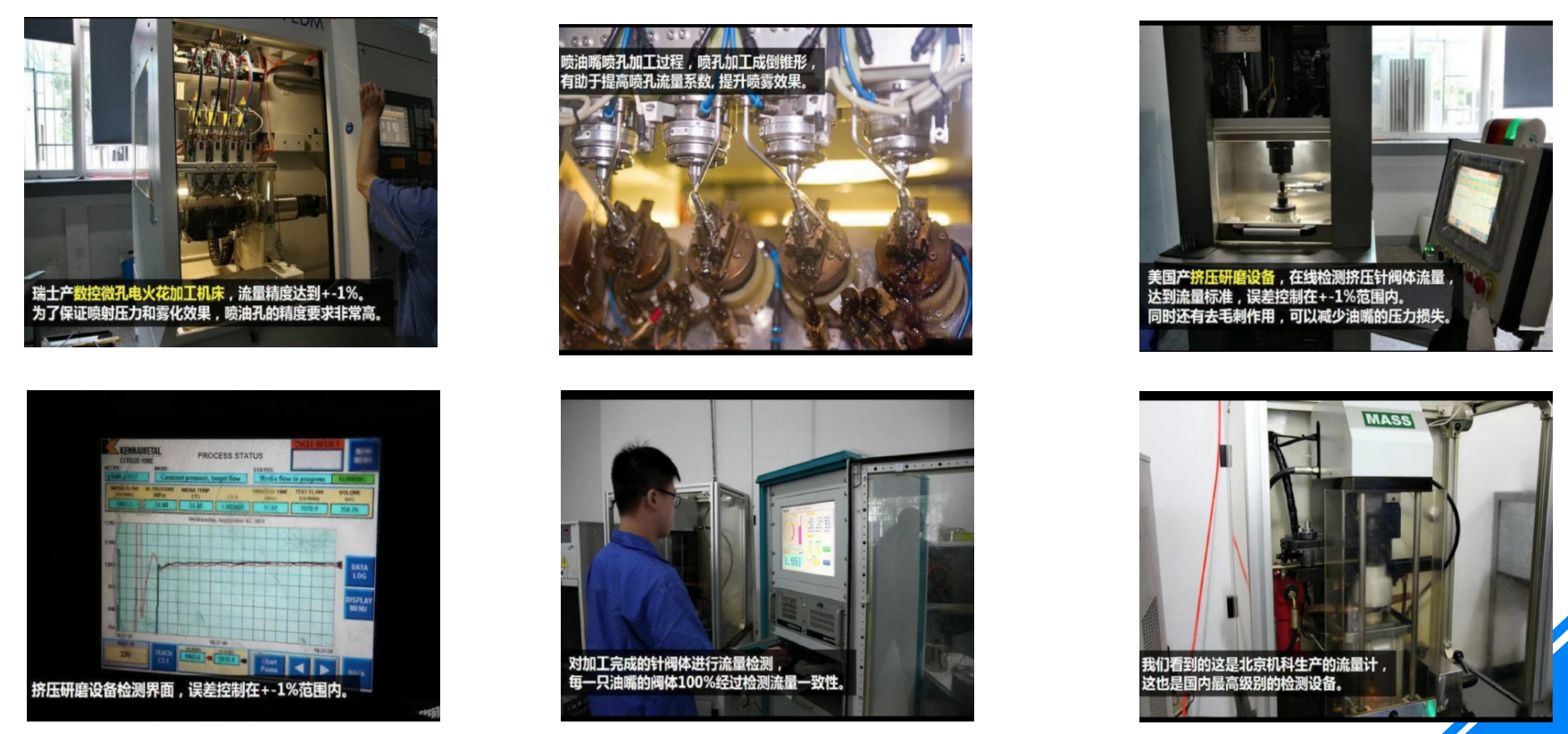

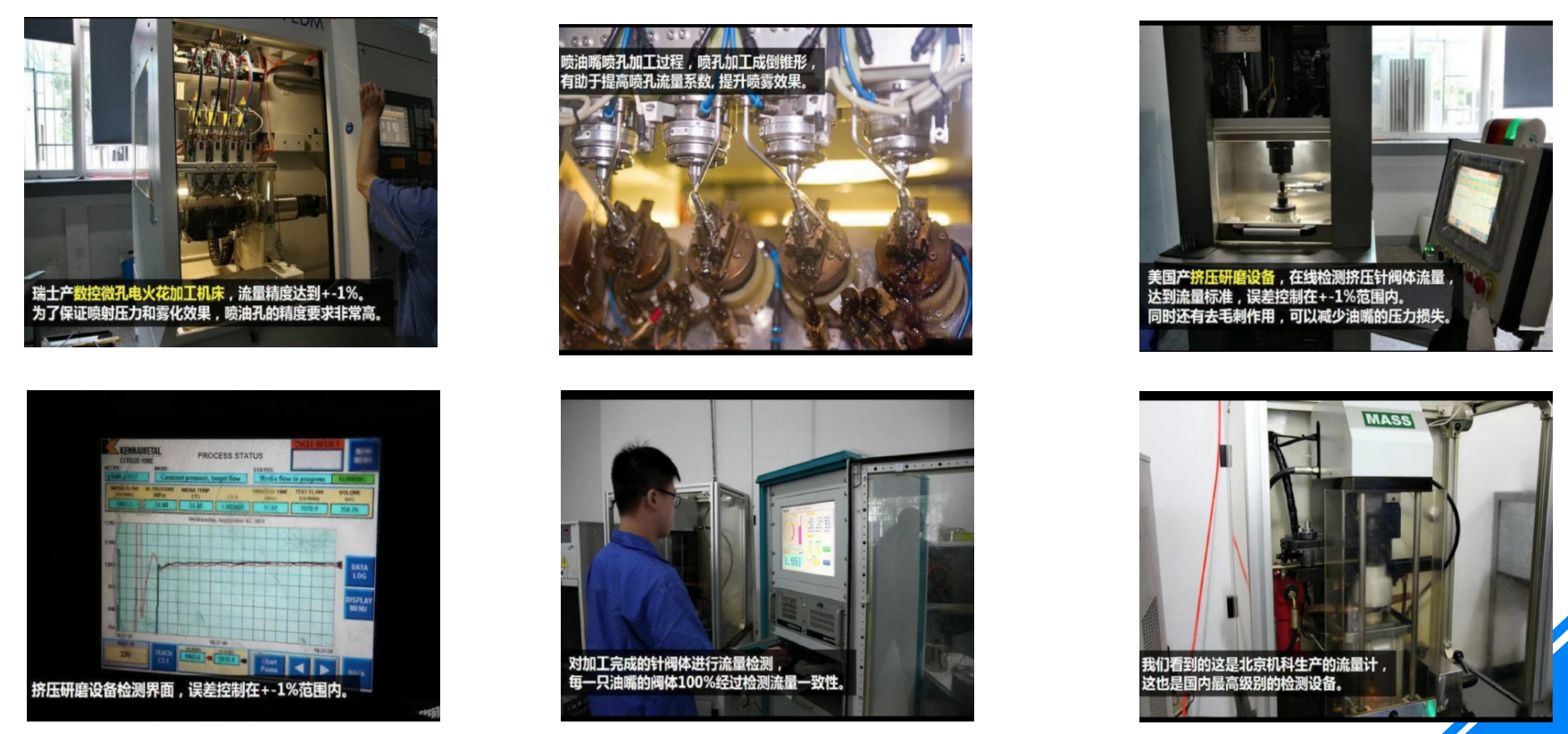

In order to ensure the injection force and effect of the injector, the accuracy of the injection hole is required to be very high, and the injection hole needs to be completed

Inverted cone, help to improve the flow coefficient of the jet hole, improve the spray effect, the company needs to purchase imported CNC micro

Hole EDM machine, flow accuracy can reach ±1%.

Also need to purchase imported extrusion grinding equipment, on-line detection of extrusion needle valve flow, error control in

Within the range of ±1%, the pressure loss of the nozzle can be reduced. The finished needle valve body company requires each one

Valve body of nozzle 100%. Verified flow consistency!

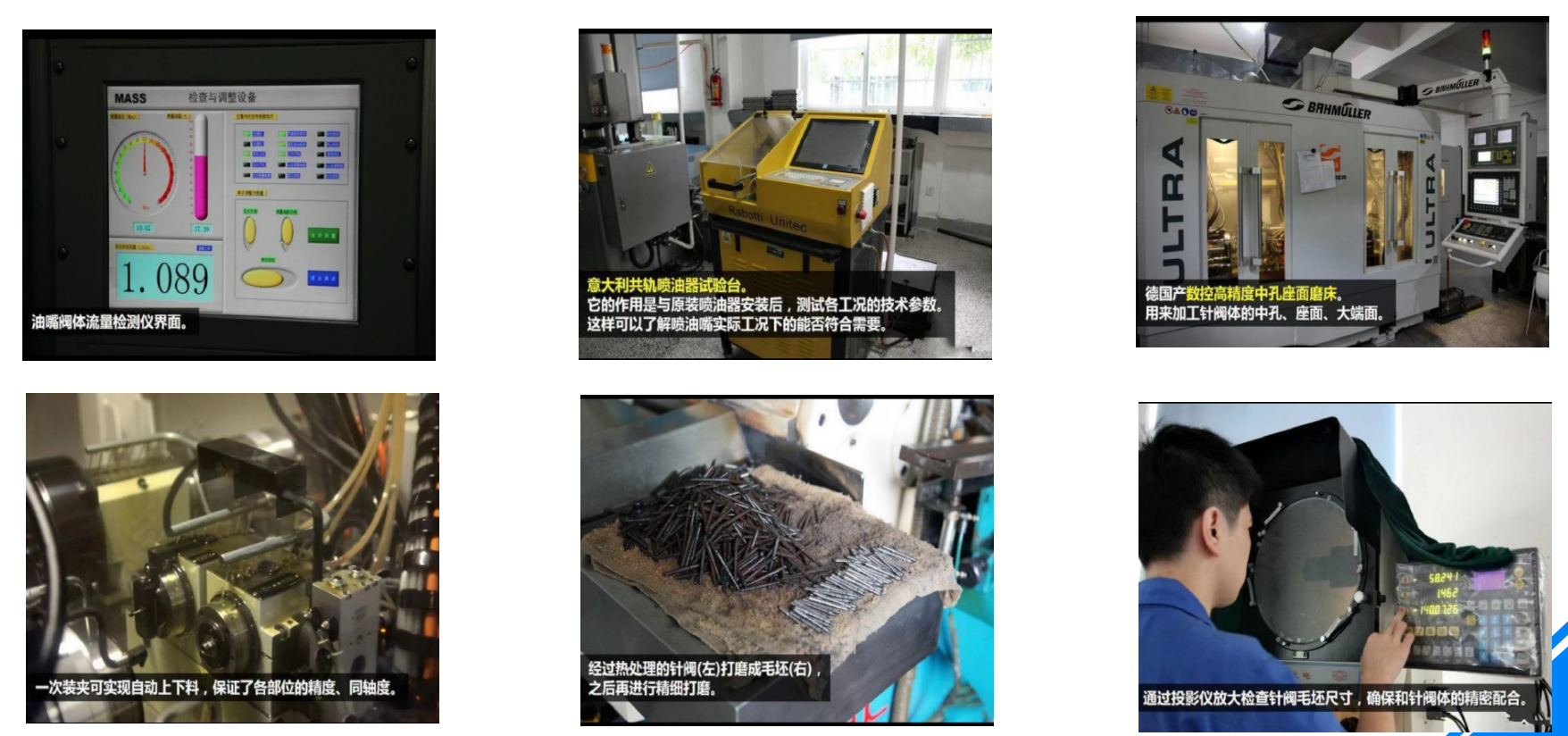

In addition, in order to better understand whether the nozzle can meet the requirements under actual working conditions, it is also necessary to spray oil

The nozzle and the original injector are tested after installation, the company uses the Italian common rail injector test rig, which

The function is to test the technical parameters of each working condition after the installation of the original injector.

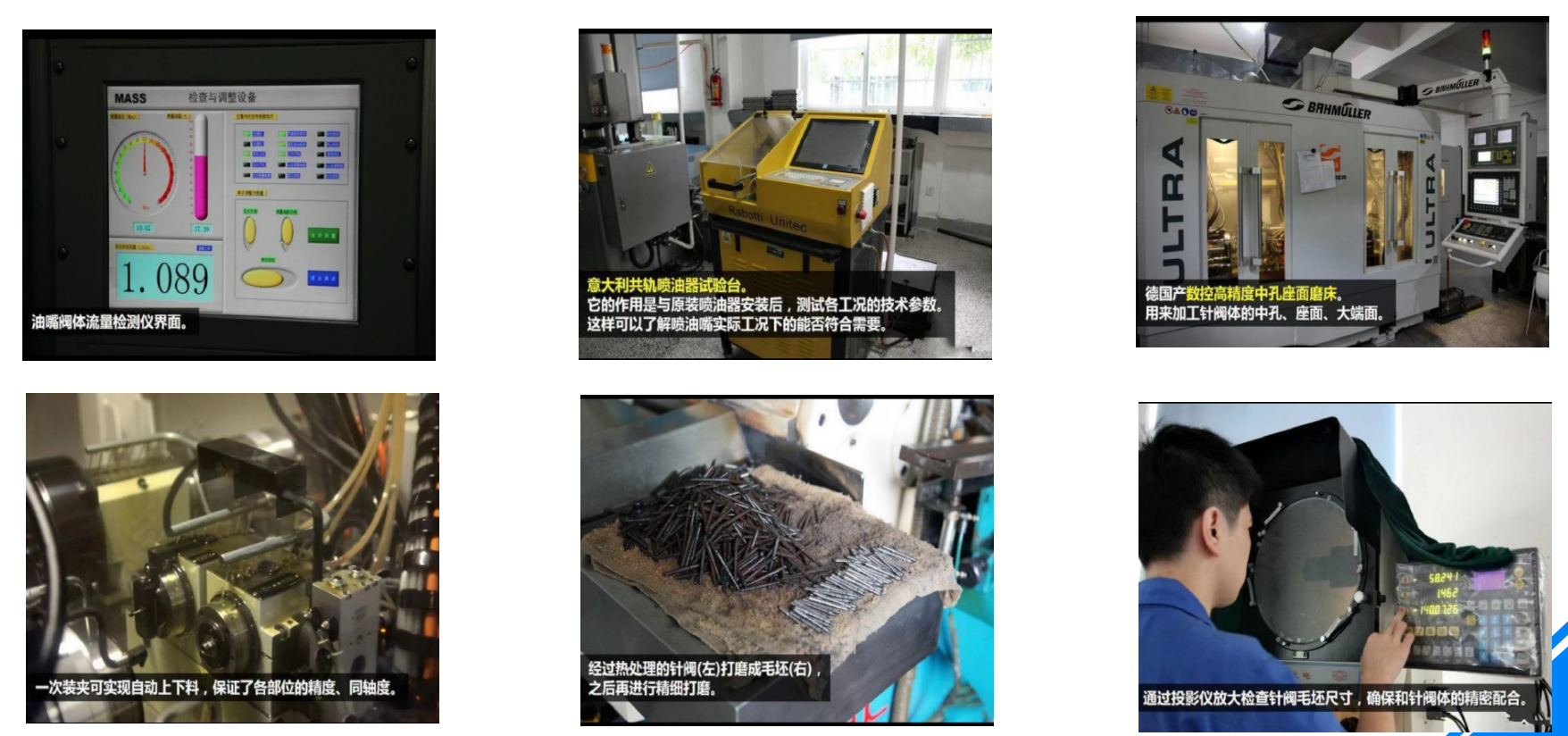

The company needs to purchase imported CNC high precision middle hole seat grinding machine to process the middle hole and seat of the needle valve body

Face, large end face. The software equipment can realize automatic loading and unloading at one time to ensure the accuracy and consistency of each part

Axial degree. In addition, the large end face is concave after grinding, which is conducive to assembly and sealing with the injector body.

After the heat treatment of the needle valve, after rough grinding to form a wool embryo, through the projector to enlarge the inspection needle

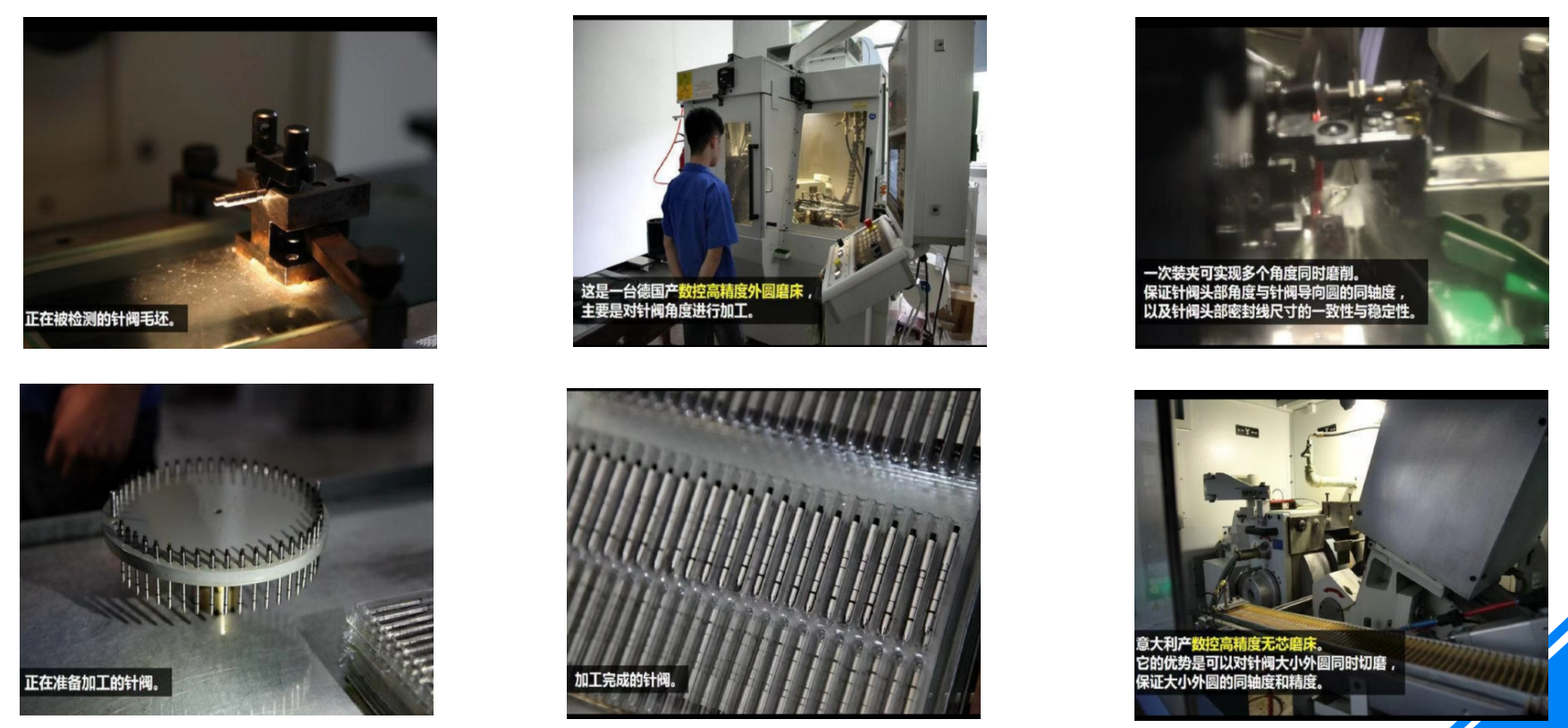

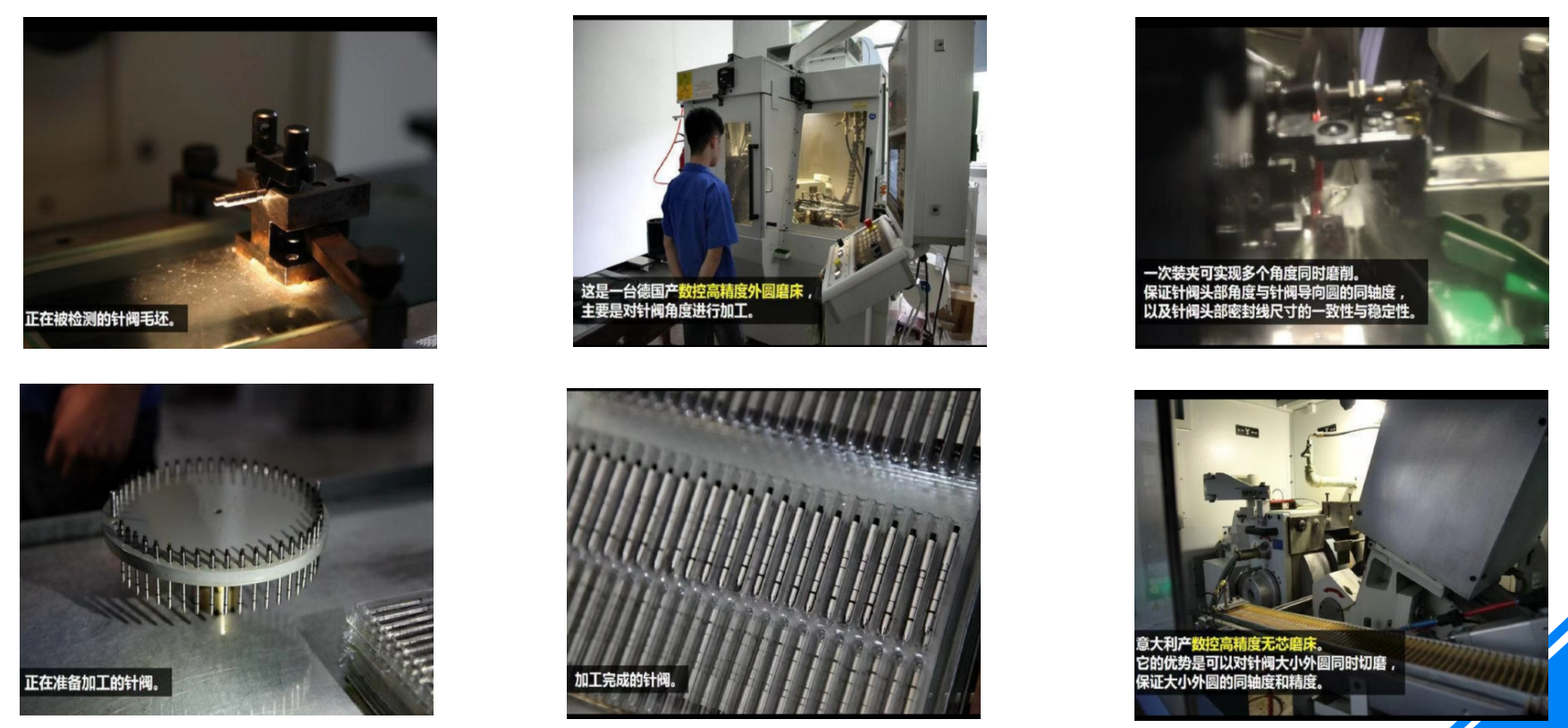

Valve blank size ensures a precise fit with the needle body. After testing the needle valve needs to use imported CNC high

Precision foreign grinding machine for processing, the equipment can achieve multiple angles at the same time grinding, one-time processing

The advantage is to ensure the needle valve head Angle and the coaxial degree of the needle guide circle, and the needle valve head density

The consistency and stability of the sealing wire size, and finally the size of the needle valve and the outer circle need to be cut and ground

Finished with imported CNC high precision coreless grinding machine. The roundness of the needle valve needs to be controlled above 0.25μm, which

The sample can better meet the accuracy requirements of the common rail injector, and the needle valve and the valve body flow transduction are pumped in

The matching experiment of the pair parts is also the technical confidentiality procedure of our company, in order to ensure the accuracy and processing

Consistency, a lot of equipment needs to be imported from abroad, small fuel injection nozzle for accuracy, tension, reliability

Not to be a little vague, which also invested a lot of research and development efforts, the company spent more than five years

Time research on the processing process has achieved remarkable results.

Production process

Company's new project

The company has reached an intention to cooperate with the Russian kamaz engine plant,

Monthly supply of various injector assemblies to Kamaz for engine assembly,

The minimum supply of 30,000 pieces per month, about 30 million yuan!

In order to meet the supporting needs of Kamaz Company, the company needs to purchase 4 production lines, about 289 million yuan.

Company development plan

The company will be the following enterprises as the benchmark enterprises:

1. Bosch

2. Denso

3. Delphi

4. Borgwarner Inc

5. Siemens AG

6. Cummins, USA

The establishment is based on the domestic, facing the world's domestic first-class

Fuel system, high pressure common rail product development and production company,

Try to break the foreign common rail technology has always been the ridge

Break, strive to bring considerable economic and social effects to the domesticYes.

The company has strong technical force and has a senior team

Experts and innovative technical backbone

The research and development team, and with the University of Jinan and other higher focus

The institutions have established a good mechanism for cooperative research. us

Adhering to the concept of "science and technology people-oriented", we focus on talents

Quality, high-tech development as a strategic goal, adhere to the "customer.

Households first, market-oriented "principle, to provide customers

Advantage products and services to create and share with partners

Successful value chain, the company has been based on research and development,

Has a strong R & D force, committed to technology innovation

New, the improvement of research and development strength and the completion of service system

Good.

The company is entering a new stage of development

Strong technical, manufacturing, purchasing, marketing and management excellence

Potential, with an excellent team to build Chinese car engines

Core component brand.

Business introduction

The company now produces mechanical and electronically controlled fuel systems to meet

Road diesel engine country III to country II, non-road country III and

Emission requirements for country IV. Widely used in automotive diesel engines, workers

Cheng machinery, generator set, ship machinery and other fields, the main products

Yes; Light, medium, heavy and heavy-duty common-rail fuel injection

Systems, SCR post-processing systems, mechanical in-line pumps and pumps

Nozzle, electric control in line pump system, imported foreign fuel system

Production technology, dedicated to the development of internal combustion engine intake system, low

Pressure hydrogen subsystem. Low pressure hydrogen subsystem: hydrogen ejector,

Hydrogen isolation valve, hydrogen safety valve, hydrogen circulation pump, has achieved the first batch

Customer samples, high pressure hydrogen subsystem completed A sample development

And some reliability tests; The hydrogen subsystem achieves electric increase

Pressure customer sample. To ensure high precision and reliability of products

The company will introduce advanced CNC and CNC from other developed countries

Testing equipment.

These products are supported by many domestic diesel engine factories.

And exported to America, the Middle East, Southeast Asia and other regions, annual sales

300 to 400 million.

Company product advantage

The injection nozzle produced by the company can match the three common rail series of Bosch, Denso and Delphi.

The oil nozzle is roughed by the imported Eurya quadricol drilling machine. Eurya quad drill once

Spray clamp, injector hole molding once, one processing molding can ensure concentricity, straightness and roughness

The degree meets the requirement. The use of electrochemical electrolysis tank to ensure the size of the tank while ensuring that there is no hair

S. The original process is to dig in with a knife, which is short for products with such high precision as the oil nozzle

The point is that there are more burrs and the shape is irregular, which can be solved well by electrochemical electrolysis

Question, this is also a big breakthrough for the company!

In order to ensure the injection force and effect of the injector, the accuracy of the injection hole is required to be very high, and the injection hole needs to be completed

Inverted cone, help to improve the flow coefficient of the jet hole, improve the spray effect, the company needs to purchase imported CNC micro

Hole EDM machine, flow accuracy can reach ±1%.

Also need to purchase imported extrusion grinding equipment, on-line detection of extrusion needle valve flow, error control in

Within the range of ±1%, the pressure loss of the nozzle can be reduced. The finished needle valve body company requires each one

Valve body of nozzle 100%. Verified flow consistency!

In addition, in order to better understand whether the nozzle can meet the requirements under actual working conditions, it is also necessary to spray oil

The nozzle and the original injector are tested after installation, the company uses the Italian common rail injector test rig, which

The function is to test the technical parameters of each working condition after the installation of the original injector.

The company needs to purchase imported CNC high precision middle hole seat grinding machine to process the middle hole and seat of the needle valve body

Face, large end face. The software equipment can realize automatic loading and unloading at one time to ensure the accuracy and consistency of each part

Axial degree. In addition, the large end face is concave after grinding, which is conducive to assembly and sealing with the injector body.

After the heat treatment of the needle valve, after rough grinding to form a wool embryo, through the projector to enlarge the inspection needle

Valve blank size ensures a precise fit with the needle body. After testing the needle valve needs to use imported CNC high

Precision foreign grinding machine for processing, the equipment can achieve multiple angles at the same time grinding, one-time processing

The advantage is to ensure the needle valve head Angle and the coaxial degree of the needle guide circle, and the needle valve head density

The consistency and stability of the sealing wire size, and finally the size of the needle valve and the outer circle need to be cut and ground

Finished with imported CNC high precision coreless grinding machine. The roundness of the needle valve needs to be controlled above 0.25μm, which

The sample can better meet the accuracy requirements of the common rail injector, and the needle valve and the valve body flow transduction are pumped in

The matching experiment of the pair parts is also the technical confidentiality procedure of our company, in order to ensure the accuracy and processing

Consistency, a lot of equipment needs to be imported from abroad, small fuel injection nozzle for accuracy, tension, reliability

Not to be a little vague, which also invested a lot of research and development efforts, the company spent more than five years

Time research on the processing process has achieved remarkable results.

Production process

Company's new project

The company has reached an intention to cooperate with the Russian kamaz engine plant,

Monthly supply of various injector assemblies to Kamaz for engine assembly,

The minimum supply of 30,000 pieces per month, about 30 million yuan!

In order to meet the supporting needs of Kamaz Company, the company needs to purchase 4 production lines, about 289 million yuan.

Company development plan

The company will be the following enterprises as the benchmark enterprises:

1. Bosch

2. Denso

3. Delphi

4. Borgwarner Inc

5. Siemens AG

6. Cummins, USA

The establishment is based on the domestic, facing the world's domestic first-class

Fuel system, high pressure common rail product development and production company,

Try to break the foreign common rail technology has always been the ridge

Break, strive to bring considerable economic and social effects to the domesticYes.